The crankshaft position sensor plays a crucial role in ensuring the smooth operation of your vehicle’s engine by providing crucial data to the engine control unit. However, like any other car component, the crankshaft sensor can sometimes malfunction causing various issues. Here we will discuss temporary fixes for a faulty crankshaft position sensor and what steps to take after replacing it. Whether you’re facing problems with your sensor or just want to be prepared, read on to discover valuable insights.

The Importance of Regular Maintenance

Regular vehicle maintenance is crucial for preventing sensor issues and ensuring the overall health of your car, regardless of make and model. Here are some maintenance tasks that can help you avoid crankshaft position sensor problems in the first place:

- Oil Changes: Regular oil changes keep the engine lubricated and running smoothly. Dirty or low-quality oil can lead to sensor issues.

- Air Filter Replacement: A clean air filter ensures that the engine gets the proper air-to-fuel ratio, reducing strain on the sensor and helping maintain the ECU in good condition.

- Fuel System Cleaning: Cleaning the fuel system can prevent buildup in the engine, which can affect sensor performance.

- Timing Belt Inspection: A worn timing belt can cause sensor misalignment. Regular inspections of the crankshaft sensor can catch this issue before it becomes a problem.

- Check Engine Light: If your check engine light comes on, don’t ignore it; it could indicate a malfunctioning crankshaft position sensor. Have the codes checked promptly to address any sensor-related problems early, as a bad crankshaft sensor can impact vehicle performance.

- Regular Sensor Inspections: Include crankshaft position sensor inspections in your routine vehicle checkups. Catching sensor issues early can prevent major breakdowns.

Common Symptoms of a Failing Crankshaft Position Sensor

While we’ve discussed temporary fixes and long-term solutions, it’s essential to recognize the common symptoms of a failing crankshaft position sensor. Being aware of these signs can help you take action promptly if a sensor fails:

- Check Engine Light: The most common indicator of a sensor problem is the illumination of the check engine light on your dashboard.

- Stalling: A malfunctioning sensor can cause your engine to stall, especially at low speeds or while idling, indicating a potential problem with the engine control unit.

- Rough Idling: If you notice your engine running unevenly or experiencing rough idling, it could be a sign of sensor trouble.

- Poor Fuel Efficiency: A failing sensor can lead to poor fuel efficiency, causing you to use more gas than usual. This is especially true if the sensor fails.

- Difficulty Starting: This could be a sign of a failing crankshaft sensor. Problems with the sensor can make it difficult to start your vehicle, leading to extended cranking times.

- Loss of Power: A faulty crank sensor may cause the engine to lose power intermittently. You may experience a significant loss of power while driving if the sensor is failing.

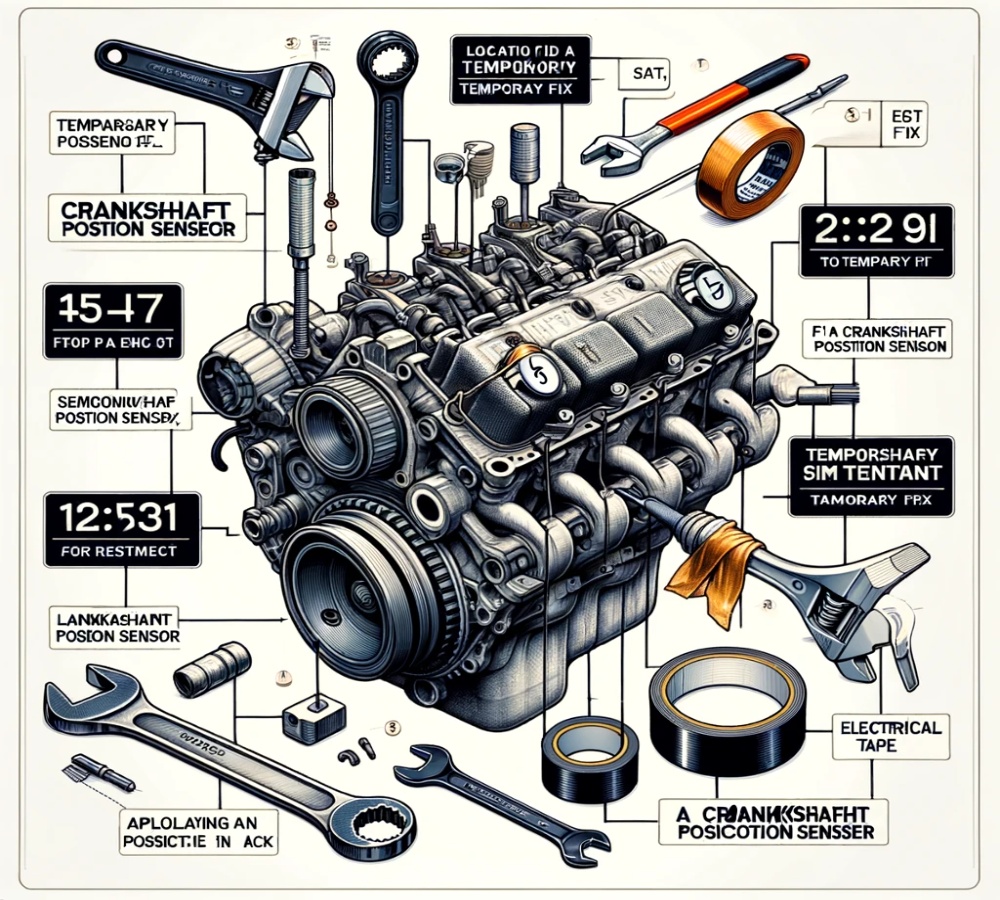

Temporary Fix for a Faulty Crankshaft Position Sensor

When your vehicle’s crankshaft position sensor starts acting up, it can lead to a range of problems, including rough idling, stalling, and poor fuel efficiency. While a long-term solution involves replacing the sensor, there are a few temporary fixes that can help you get back on the road safely:

- Clean the Sensor: Ensuring the crankshaft sensor is clear of debris can prevent malfunction. Sometimes, a malfunctioning sensor may be due to dirt or debris buildup on the crankshaft sensor. Locate the sensor (usually near the crankshaft pulley on the engine block) and carefully clean it using a sensor-safe cleaner to avoid damage to the engine control unit (ECU). This might resolve minor issues caused by contamination.

- Check Wiring Connections: Inspect the wiring harness connected to the sensor terminal. Loose or damaged wires can cause erratic readings, which may affect the ECU. Ensure all connections to the crankshaft sensor are secure and free from corrosion, and also check the camshaft position sensor connections. Repair or replace damaged wires as needed.

- Inspect for Physical Damage: A damaged sensor can be a common issue. Look for any visible signs of physical damage, such as cracks or corrosion. If you find any, it’s best to replace the sensor.

- Check for Fault Codes: An OBD-II scanner can detect issues related to the crankshaft sensor, providing a fix for the crankshaft position problems. Modern vehicles are equipped with onboard diagnostics (OBD-II) systems that can store fault codes related to the crankshaft position sensor and the engine control unit. Use an OBD-II scanner to retrieve these codes and diagnose the specific crankshaft sensor issue.

- Temporary Bypass: In some cases, a temporary bypass may be possible. Consult your vehicle’s repair manual or a qualified mechanic to determine if this is a viable option. Keep in mind that a bypass should only be considered as a last resort, and it is only a temporary fix for the crankshaft position sensor.

What to Do After Replacing the Crankshaft Position Sensor

Once you’ve successfully replaced the crankshaft position sensor, it’s essential to take a few additional steps to ensure your vehicle runs smoothly:

- Clear Fault Codes: Use an OBD-II scanner to clear any fault codes that may have been triggered by the faulty sensor. This will reset the engine control module (ECM) and allow it to adapt to the new crankshaft sensor.

- Perform a Test Drive: Take your vehicle for a test drive to ensure that the issues you were experiencing, such as rough idling or stalling, have been resolved. Make sure to start the engine and observe any changes. Pay close attention to how the engine behaves, especially if you suspect a bad crankshaft position sensor as it can affect fuel injection timing.

- Monitor for Recurrence: If the issue persists, the crank sensor might be failing. Keep an eye on your vehicle’s performance in the days and weeks following the sensor replacement. Sometimes, intermittent issues can reappear, indicating that there may be other underlying problems.

- Regular Maintenance: To prevent future sensor issues and ensure the longevity of your vehicle, adhere to a regular maintenance schedule. This includes routine sensor inspections and replacements as needed to ensure the speed of the crankshaft is properly monitored.

A faulty crankshaft position sensor can cause a range of issues in your vehicle, but there are temporary solutions to help you get by until a proper replacement can be done. Once the sensor is replaced, it’s crucial to clear fault codes and monitor your vehicle’s performance. Remember that proper maintenance is key to keeping your vehicle running smoothly in the long run.

For more automotive tips and solutions, visit Fix Australia’s website, where you’ll find valuable information on various fixes and maintenance procedures for your car. Whether it’s fixing scratches on cars, toilet seat fixing kits, or attaching shade cloth to a metal frame, Fix Australia has you covered.

Explore more articles and resources here:

- Fixing Scratches on Cars

- Toilet Seat Fixing Kits

- How to Attach Shade Cloth to Metal Frame – Fixing Method

Feel free to visit these links for additional guidance on various home and automotive fixes..