Industrial automation is a cornerstone of modern manufacturing and production processes. It enables higher efficiency, precision, and scalability. However, with increased automation comes the heightened risk of electrical failures, leading to costly downtime, reduced productivity, and even safety hazards. This is where electrical failure analysis becomes essential. By systematically identifying and addressing the root causes of electrical failures, industries can significantly enhance the resilience of their automated systems.

5 Ways Electrical Failure Analysis Boosts Industrial Automation Resilience

1. Preventing Unplanned Downtime

Unplanned downtime is one of the most disruptive and costly events in any automated industrial environment. Electrical failures, such as short circuits, component burnout, and insulation breakdown, can halt production lines abruptly. Electrical failure analysis helps in diagnosing these issues before they escalate into full-blown failures.

Electrical engineers can identify patterns that precede failures by analyzing historical data and conducting regular inspections. For instance, a recurring spike in current might indicate an impending motor failure. Armed with this information, maintenance teams can schedule proactive interventions, replacing or repairing components before they cause unplanned downtime.

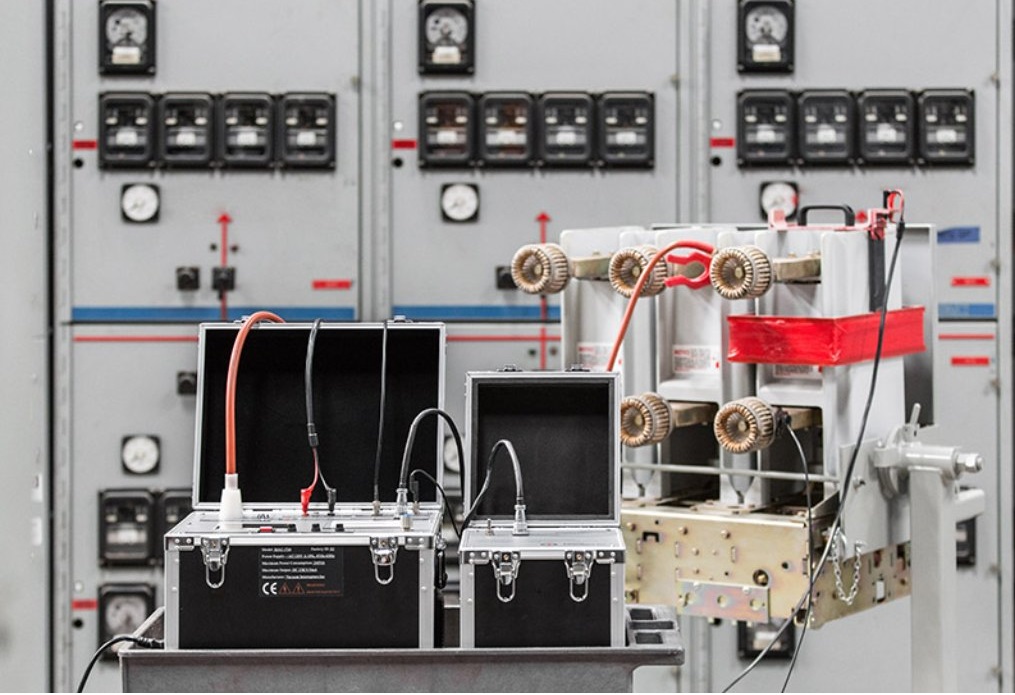

Moreover, electrical failure analysis often employs advanced diagnostic tools like thermal imaging, ultrasonic testing, and partial discharge measurements. These tools enable the detection of anomalies that are not visible to the naked eye, allowing for early intervention and significantly reducing the risk of unexpected breakdowns.

Also Read: Is Tipping Electricians Allowed?

2. Enhancing Predictive Maintenance

Predictive maintenance is a forward-thinking approach that aims to predict and address equipment failures before they occur. Electrical failure analysis is integral to this strategy. By continuously monitoring electrical systems and analysing failure data, industries can develop predictive models that forecast when and where a failure is likely to occur.

For example, vibration analysis and thermographic inspections can provide critical insights into the health of electrical components. A motor that shows unusual vibration patterns might be on the verge of bearing failure. Similarly, an overheating circuit breaker could indicate an overloaded circuit or a failing insulation system. Predictive maintenance models can use this data to schedule maintenance activities just in time, thereby avoiding unnecessary downtime and extending the lifespan of equipment.

This data-driven approach not only ensures timely maintenance but also optimizes resource allocation. Maintenance teams can focus on the components that are most likely to fail, rather than conducting routine maintenance on all parts. This targeted approach leads to more efficient operations and cost savings.

3. Improving Safety Standards

Safety is paramount in any industrial setting. Electrical failures can pose significant safety risks, including electrical shocks, fires, and explosions. Electrical failure analysis plays a critical role in enhancing safety standards by identifying and mitigating potential hazards.

For instance, an analysis of electrical insulation can reveal weaknesses that could lead to short circuits or fires. Identifying these weak points allows for timely replacement or reinforcement of insulation materials, thereby reducing the risk of accidents. Similarly, examining the condition of circuit breakers and other protective devices ensures they will function correctly during an electrical fault, preventing injuries and equipment damage.

Furthermore, electrical failure analysis often includes the investigation of past incidents to understand their root causes. By learning from previous failures, industries can implement changes to design, installation, or maintenance practices to prevent similar occurrences in the future. This continuous improvement cycle helps create a safer working environment for employees and reduces liability for the company.

4. Optimizing Energy Efficiency

Electrical failures are often linked to inefficiencies in the system. For example, a malfunctioning motor may draw more current than necessary, leading to higher energy consumption and increased operational costs. Electrical failure analysis can identify these inefficiencies and suggest corrective actions.

By analyzing the power quality and energy usage patterns, electrical engineers can pinpoint areas where energy is being wasted. For instance, harmonic distortions caused by non-linear loads can lead to overheating and reduced efficiency of electrical equipment. By addressing these issues through proper filtering or load balancing, industries can enhance their energy efficiency.

Moreover, optimizing energy efficiency has a direct impact on the resilience of industrial automation systems. Efficient systems are less likely to experience stress and failures, ensuring smoother and more reliable operations. Additionally, energy-efficient practices contribute to sustainability goals, reducing the overall carbon footprint of industrial activities.

5. Supporting Continuous Improvement and Innovation

Industries that embrace electrical failure analysis as part of their automation strategy are better positioned for continuous improvement and innovation. By systematically analyzing failures and their root causes, companies can gain valuable insights into the performance of their electrical systems and identify opportunities for innovation.

For instance, the integration of smart sensors and IoT devices allows for real-time monitoring and data collection from various components. This data can be analyzed to detect emerging trends and potential failure points. Leveraging advanced analytics and machine learning algorithms, industries can develop smarter, more resilient automation systems that learn from past failures and adapt to changing conditions.

Additionally, electrical failure analysis supports the development of new technologies and methodologies. By understanding the limitations and weaknesses of current systems, engineers can design next-generation solutions that are more robust and efficient. This continuous feedback loop fosters a culture of innovation, driving the industry forward and ensuring that automation systems remain at the cutting edge of technology.

Case Study: Electrical Failure Analysis in Action

To illustrate the impact of electrical failure analysis, consider a large manufacturing plant that experienced frequent unplanned downtime due to electrical issues. The company decided to implement a comprehensive electrical failure analysis service. Through detailed inspections, data analysis, and predictive modelling, they identified several critical areas where failures were likely to occur.

One significant finding was the deterioration of insulation in several high-voltage cables, which posed a fire risk. By replacing these cables proactively, the company prevented potential fires and improved overall safety. Additionally, the analysis revealed that several motors were operating inefficiently due to misalignment and imbalance. Correcting these issues resulted in a 15% reduction in energy consumption and extended the lifespan of the motors.

Furthermore, the company adopted a predictive maintenance approach based on the insights gained from the electrical failure analysis. They installed smart sensors to monitor key parameters and used predictive models to schedule maintenance activities. As a result, unplanned downtime was reduced by 40%, leading to significant cost savings and increased productivity.

Conclusion

Electrical failure analysis is a vital component of industrial automation resilience. By preventing unplanned downtime, enhancing predictive maintenance, improving safety standards, optimizing energy efficiency, and supporting continuous improvement and innovation, electrical failure analysis ensures that automated systems operate smoothly and efficiently. As industries continue to embrace automation, the importance of robust and reliable electrical systems cannot be overstated. Investing in electrical failure analysis not only protects assets and ensures safety but also drives operational excellence and sustainability in the long run.